Case

Genesi Elettronica case studies in different application fields

study

Sector: Food & Beverage and Quality Control.

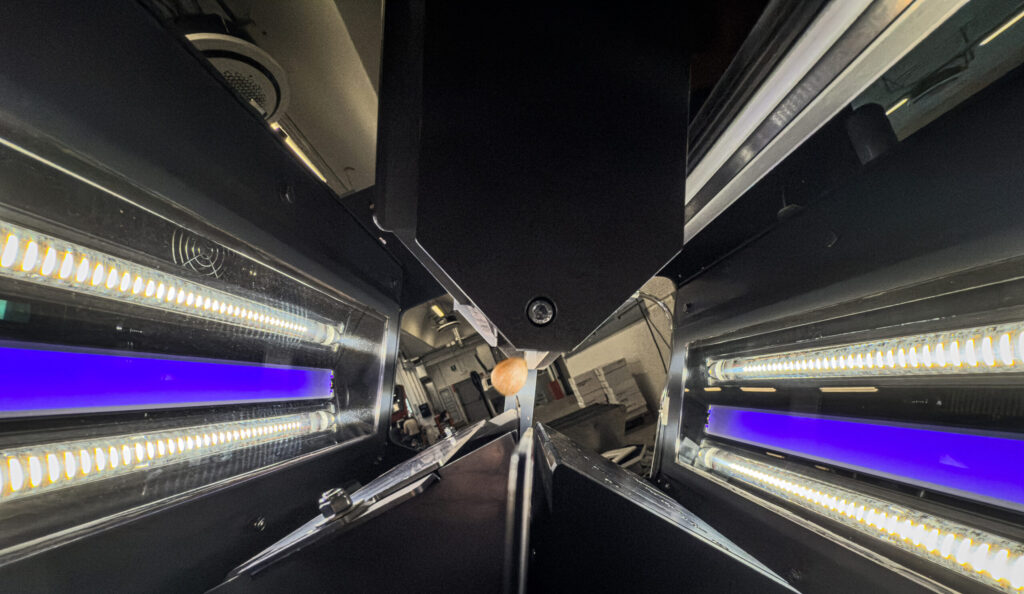

Application goal: 3D robot guide for automatic ham trimming. 3D reconstruction of the ham surface, identification of the part to be coated with AI, generation of the spraying path.

Genesi Elettronica solution: Use of GEMPC50-6K-RA24-OP-SV illuminators, ideal for structured light on 3D stereo cameras. The lighting enabled high-precision three-dimensional reconstructions to be obtained, which are essential for robotic control.

Benefits obtained:

- – Three-dimensional reconstruction faithful to the surface of the product.

- – Automatic generation of the robot path for uniform coverage.

- – Process optimisation and waste minimisation.

Sector: Sorting.

Application goal: To create an automated sorting system for hazelnuts, capable of separating the nuts according to colour and identifying the presence of foreign bodies.

Genesi Elettronica solution: Application of GEVX84-5K illuminators (high uniformity white light) combined with RGB-i 4K cameras to enable simultaneous analysis of multi-channel visual components (colour + NIR).

Benefits obtained:

- – High precision in identifying non-compliant hazelnuts.

- – Detection capability even on difficult surfaces, thanks to the synergy between RGB and NIR cameras.

- – Improved efficiency in selection and reduction of manual waste.

Sector: Industry 4.0 / Mechanical automation.

Application goal: Optimised setup for detecting and classifying defects or anomalies on components in line using AI algorithms.

Genesi Elettronica solution: GEL182‑6K‑OP‑FS‑S illuminator, centrepiece of a system with Edge-Vision-4.0 (12 MP camera + AI capability). The uniform light enables vision software to reliably detect anomalies.

Benefits obtained:

- – Automation of defect detection with artificial intelligence.

- – High resolution for detailed surface analysis.

- – Improved performance and fewer manual interventions.

Sector: Defect detection and Quality Control.

Application goal: To make visual recognition of threads on metal bolts reliable in production contexts, ensuring accuracy even on reflective surfaces.

Genesi Elettronica solution: Use of a Genesi LED backlight system (model GB – Genesi Backlight), positioned behind the component to create high-contrast silhouettes, combined with an industrial camera with matrix acquisition.

Benefits obtained:

- – Marked contrast between edge and background, suitable for automatic recognition algorithms.

- – Robust acquisition even on shiny or metallic surfaces.

- – Greater reliability of the vision system compared to systems based solely on front lighting.

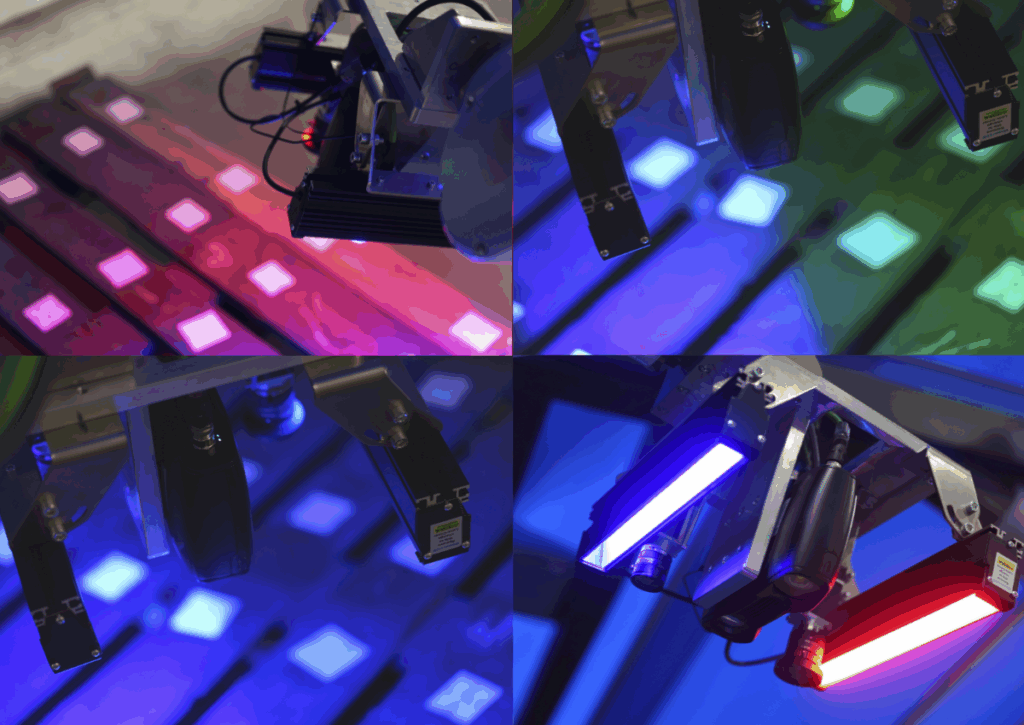

Sector: Quality Control.

Application goal: To ensure accurate quality control of pallets during handling and storage processes by detecting structural defects or irregularities.

Genesi Elettronica solution: The vision system integrates two types of Genesi illuminators:

- – GEVXD28-405-TN-M12S: 405 nm UV illuminator for inspecting surfaces and materials with selective fluorescence.

- – GEVXD28-MSB-RGB-1550: multispectral illuminator, capable of operating at different wavelengths, ensuring advanced analysis of textures and materials.

The lighting was combined with a 3D camera and a SWIR camera, creating a hybrid system capable of combining the depth of three-dimensional vision with spectral analysis of surfaces.

Benefits obtained:

- – Precise identification of structural defects (cracks, deformations, broken elements) thanks to 3D vision.

- – Detection of material anomalies and contamination thanks to SWIR and UV sensitivity.

Genesi Elettronica Srl

- © 2024 Genesi Elettronica Srl

- P.IVA IT02100940366

- Legal Notes

- Privacy Policy

- Cookie Policy

- This site is protected by reCAPTCHA and the Google Privacy Policy

- Terms of Service

- Website by NewLogic srl

- © 2024 Genesi Elettronica Srl

- P.IVA IT02100940366

- Legal Notes

- Privacy Policy

- Cookie Policy

- This site is protected by reCAPTCHA and the Google Privacy Policy

- Terms of Service

- Website by NewLogic srl